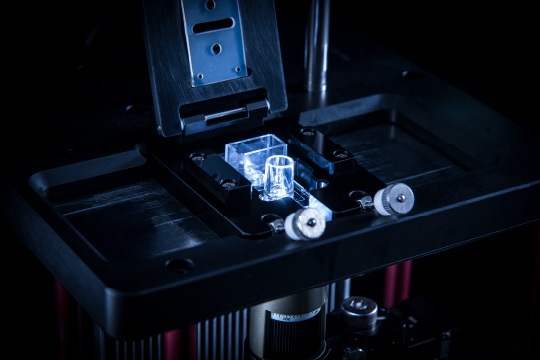

On-chip Droplet Generator allows mass production of micrometer-sized water-in-oil (W/O) emulsion droplets and gel microdrops (GMDs) with a unique microfluidic chip. The individual droplets function as miniaturized vessels for reactions such as microbial/cell cultivation and genetic analysis. Droplet technology is now recognized as a prominent high-throughput screening method allowing single cell analysis or simultaneous assay of more than 1 million samples.

FEATURES

Generation of stable droplets

Generation of stable droplets-

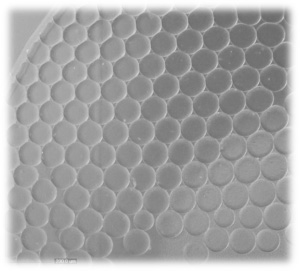

On-chip Droplet Generator allows production of stable and monodisperse droplets.

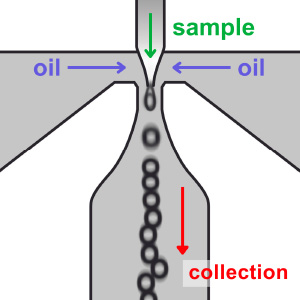

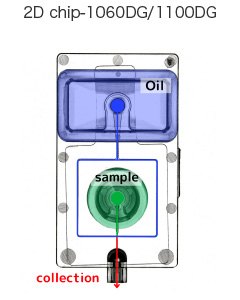

Structure of microchannel  Easy adjustment of droplet size

Easy adjustment of droplet size-

Droplet size can be easily adjusted between 60 µm and 220 µm in diameter by regulating the pressure applied to the sample and oil reservoirs.

See “Reagents/Chips” page for details for each microfluidic chip used for Droplet Generator

Real-time monitoring of droplet generation

Real-time monitoring of droplet generation-

Droplet size can be viewed and monitored real-time with the supplied monitoring device.

Types of droplets generated

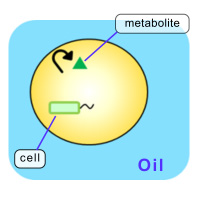

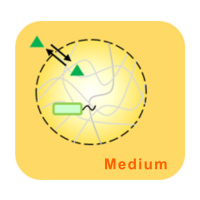

On-chip Droplet Generator can produce two types of droplets: water-in-oil (W/O) emulsion droplets and gel microdrops (GMDs).

W/O droplet |

GMD |

|

|---|---|---|

| No. of droplets | ≥ 1 million droplets | ≥ 1 million droplets |

| Contents | Aqueous liquid (medium, etc.) | Solid (agarose, gelatin, etc.) |

| Transfer of substances | Maintained inside (depending on polarity) | Extracellular fluid including reagent infiltrates the inside |

| Usage | Environmental microbial screening, etc. | Variant screening, etc. |

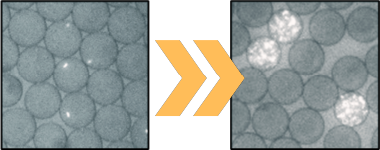

| Immediately after encapsulation After cultivation |

E. coli |

Lung cancer-derived cell line |

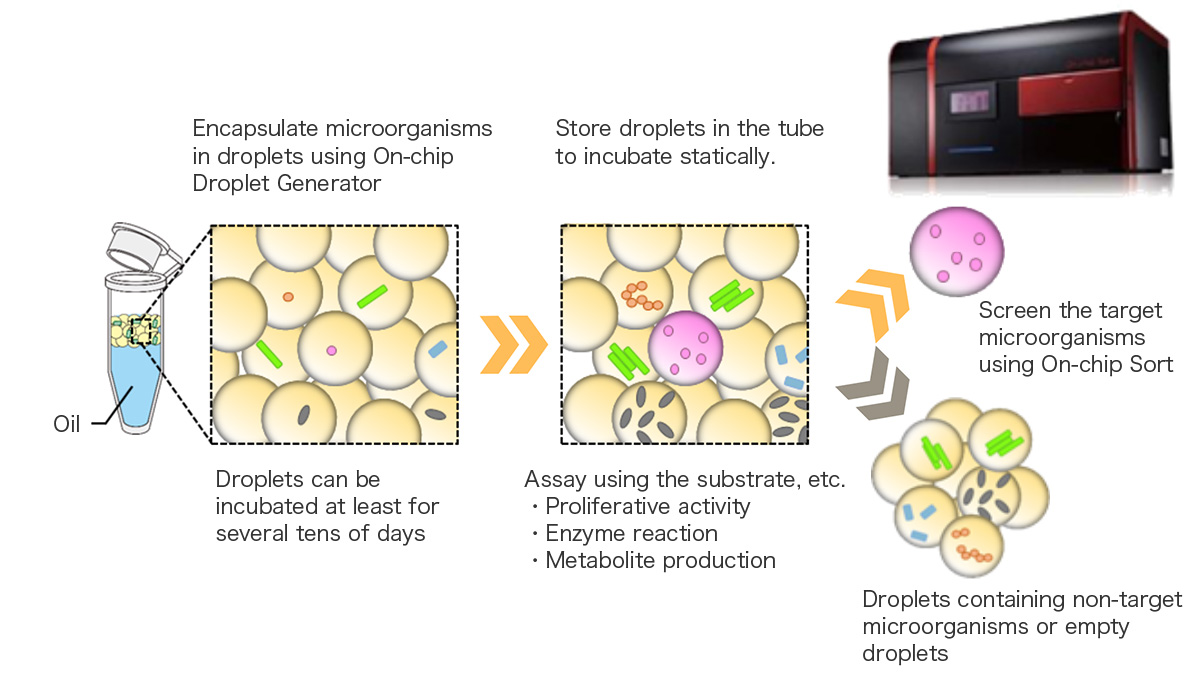

Utilization of On-chip Droplet Generator and On-chip Sort

On-chip Sort utilizes microfluidic chip technology that allows oil to be used as sheath fluid, which makes the selection of W/O droplets with microorganisms possible.

See also “On-chip Sort” page for details.

On-chip Droplet Selector is used in various research areas.

See also “Application|Droplet” for details of droplet technology.

SPEC & Product Information

Main unit size

| Size | 270 (W) x 270 (D) x 280 (H) mm |

|---|---|

| Weight | 10kg |

Main unit

| Liquid delivery pressure | 0.1 – 80 kPa |

|---|---|

| Maximum liquid delivery line | 3 lines (sample, oil, other reagents) |

| Droplet size generated | Diameter 60 – 220 μm (can be adjusted discretionally) |

| Generation rate | Approx. 100,000 droplets/3 min (for generation of 100 μm droplets) |

| Regulation | Laptop PC (Windows 10) |

| Power input | AC 100-240V, 50/60Hz |

| Power consumption | 1.2A typ (ACIN 100V) |

Monitoring unit

| Size | 215 (W) x 310 (D) x 430 (H) mm |

|---|---|

| Accessories | Monitor camera, Peltier unit, Controller |

| Temperature range | ー5 ~ 70℃ |

| Ambient environment | Temperature 5 – 40˚C, humidity ≤ 85% RH |

| Power input | DC24 V |

| Power consumption | 6.5 A max |

On-chip Droplet Generator Product List

| Product Number | Product Name | Specifications |

|---|---|---|

| 60003 | On-chip Droplet Generator (Monitoring unit with temperature control) | Main unit, chip holder, monitoring unit with temperature control |

| 60002-b | On-chip Droplet Generator (EU Model) | Instrument only Monitoring unit without temperature control & DG1 Chip holder |

Product model varies depending on the region. Please contact us for details.